A new technology

for precise cuts of different materials

Innovative high-pressure, high-precision waterjet cutting system to work on a wide range of materials:

from rubber to plastic, from wood to marble to granite, along with iron, stainless steel, brass, copper, and lead.

Ability to cut

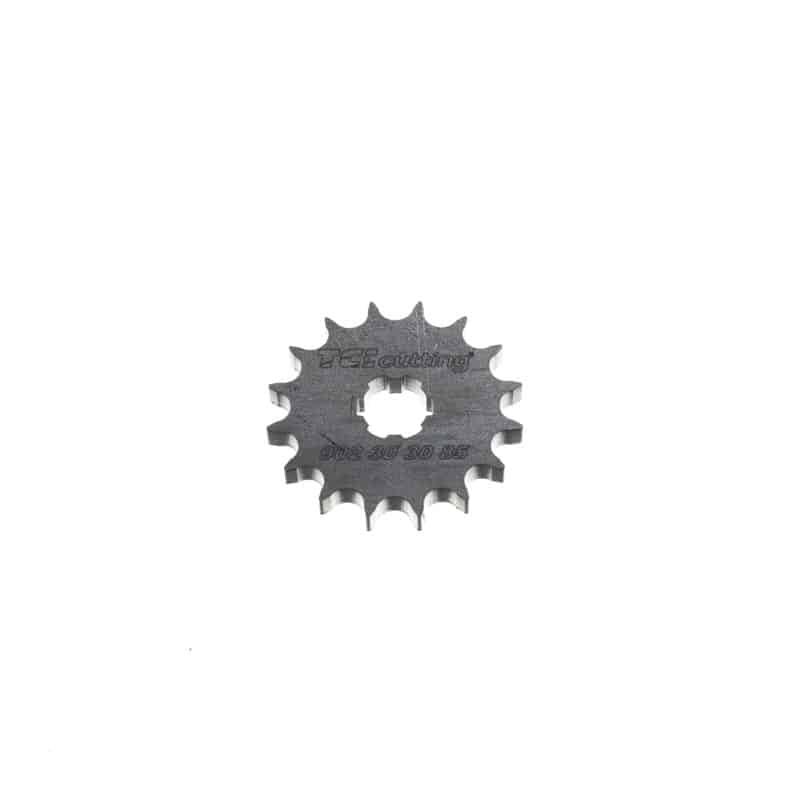

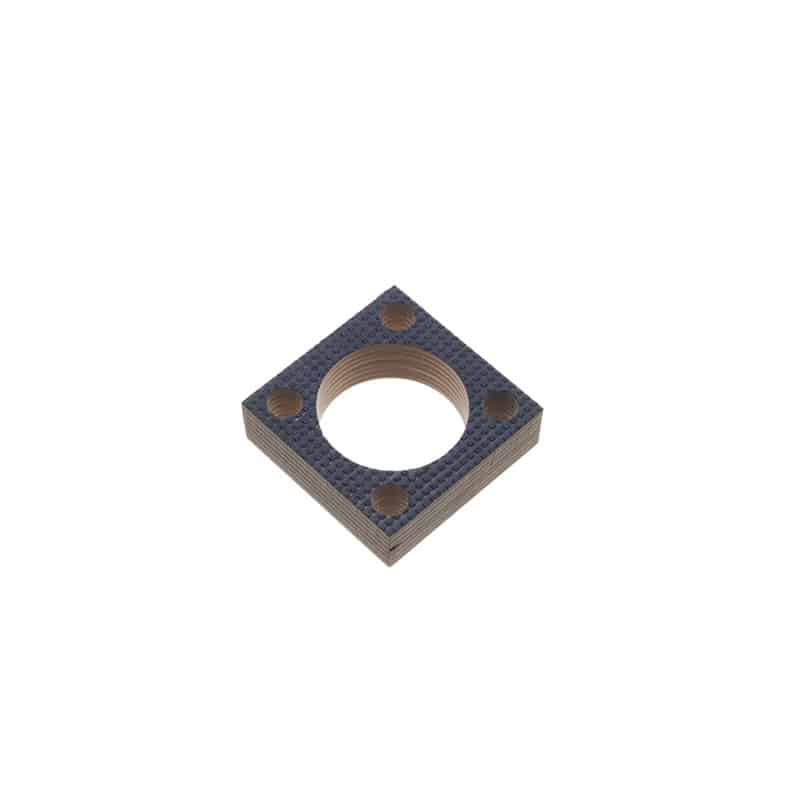

a wide variety of materials

Over the past 20 years we have constantly renovated and expanded our equipment, and today we are able to cut, shape and drill any type of material, even very thick ones, in a fast and precise manner, without any physical alteration, mechanical deformation, or structural modification of the material itself.

We offer waterjet cutting services, satisfying all your needs in a short time.

For many years we have been tending to customers with a wide range of needs, from supplying single parts to the production of mass-produced components, from cutting simple shapes to cutting more complex ones.

cutting

Technologically advanced waterjet

How the waterjet technique works

Waterjet technology was created within the aerospace field and consists of an incredible high level technique that uses water at very high pressure, paired with an abrasive substance, to cut metal materials and other thick or hard ones, resulting in an efficient solution for a wide range of materials.

Our waterjet cut works through a booster pump, that creates really high pressure, generating a water jet. Through this technique, therefore, pressure is ‘transformed’ into speed, greatly reducing the size of the water jet.

The advantages of waterjet processing

Thanks to our waterjet cutting service you will be able to perform precise cutting on the most varied materials, such as stainless steel, steel, iron, but also non-ferrous pieces, such as plastics, brass and aluminum.

Furthermore, there is no deformation due to the action of heat following the use of the waterjet technique, in fact pathogenic vapors and fumes do not develop and the surfaces do not overheat. Another advantage that should not be underestimated is the economic side, in fact the costs of waterjet cutting are quite low.

Ultimately, this particular technology guarantees:

- Elevated quality of cutting;

- savings on working costs;

- material integrity;

- high operating speed;

- elimination or reduction of consequent processing of parts;

- centesimal precision;

- Cutting of stratified or composite materials with non uniform thicknesses.

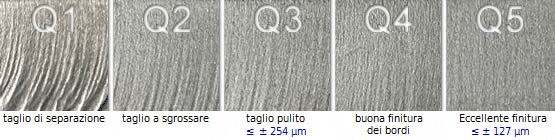

Cutting precision

Waterjet cutting offers excellent results without the need for extra finishing processes. The quality though depends on the speed of the cut. Additionally the chemical properties of the cut material do not change, because waterjet cutting does not harden the material itself.

Quality of the cutting edges performed with waterjet cutting

The materials

A great advantage of the waterjet cutting technology lies in its variety: with a waterjet cutting system it is possible to cut not only thin material, but also thick materials up to 150-200 mm.

Whether it’s aluminum, glass, plastic or steel, a waterjet cutting machine can cut any material.

Metal

Titanium

Steel

Carbon fiber

Plastic

Stone

Glass

Rubber

Composite

Foam plastic

Ceramic

Wood

Ask for a quote

Do you have a project in mind or are you looking for a partner that can side with you or build your finished products for you? Don’t hesitate!

Fill out the following form attaching a copy of your work and one of our technicians will contact you to give you more information about the timing and feasibility of your project.